-

Industrial Steel Grating

-

Serrated Steel Grating

-

Heavy Duty Steel Grating

-

Grating Trench Cover

-

Anti Slip Grating

-

Steel Stair Treads Grating

-

Fiberglass Grating Panels

-

Stainless Steel Grating

-

Aluminum Bar Grating

-

Metal Fence Clips

-

Expanded Metal Sheet

-

Perforated Metal Plate

-

Welded Mesh Fence

-

Chain Link Fence

-

Gabion Wire Mesh

-

Stainless Steel Mesh

-

Metal Filter

-

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories.

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories. -

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient.

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient. -

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

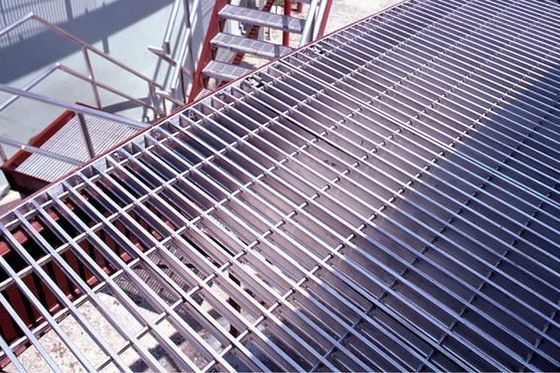

Stainless Flooring Draining Press Locked Steel Grating

| Place of Origin | China Anping |

|---|---|

| Brand Name | TT |

| Certification | ISO 9001 |

| Model Number | Q235 |

| Minimum Order Quantity | 50sqm |

| Price | U.S 22.5-20.2 sq.m |

| Packaging Details | Wooden Pallet/Steel Pallet Or As The Customar require |

| Delivery Time | 15days |

| Payment Terms | T/T, L/C, D/A, Western Union, MoneyGram |

| Supply Ability | 500sq.m per days |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Texture | Stainless Steel | Material | Steel,Q235 |

|---|---|---|---|

| Type | Plain Bar Grating,Serrated Bar Grating,serrated | Application | Floor,Walkway,stair Tread,bridge |

| Color | Silver,black,Silver Or As Your Requirement | Standard | ISO9001 |

| Size | Customized | ||

| Highlight | draining press locked steel grating,stainless press lock grating Q235,press locked steel grating Q235 |

||

FRAMED PRESSURE LOCKED GRATINGS IN STAINLESS STEEL

Stainless steel delivers the highest quality grating material with an exceptional finish.

Horizontal applications

Prestigious flooring with specific markets in the food, pharmaceutical and chemical industries

Vertical applications

Balustrades, balconies, screening

Pressure locked gratings are constructed entirely from flat bars by pressing an arrangement of cross bars into notched bearing bars. The bars are

further secured by a choice of flat wrap-around framing bar, producing a custom-sized grating panel with perfectly formed intersections.

This manufacturing method is extremely adaptable and the production process can promptly provide grating panels in custom sizes and to non-standard

specifications of weight, aperture and performance.

Alternative grades of stainless steel:

AISI 304 for general purpose

AISI 316 for exposure to harsh substances or marine conditions

TREATMENTS FOR STAINLESS STEEL All gratings are generally subject to finishing treatments such as de-greasing, pickling and polishing to reduce surface roughness, eliminate burrs from processing and maximise resistance to corrosion. Corrosion Austenitic stainless steels have a characteristic layer of chrome oxide on the surface (created by air or produced artificially) which is very thin and invisible and which protects the material from environmental damage: this resistance mainly depends on the percentage of chrome and nickel. When the formation of this layer of chrome oxide is prevented or when this layer is continually destroyed, austenitic stainless steels will corrode. To achieve good resistance to corrosion it is therefore necessary to know the types of corrosion possible and their causes, choose the suitable alloys for each application and carefully produce a design. Finally, appropriate surface treatments need to be performed. De-Greasing An essential operation before applying any heat treatment or surface finishes (such as pickling or electro-polishing) to remove any traces of grease or dirt which could damage the material itself or could lead to spotting. De-greasing is normally done by immersion or by spraying a de-greasing agent such as FS10. When the treatment has been completed, the panels are thoroughly rinsed with cold water under pressure, which also provides a mechanical cleaning action. Pickling Pickling of the surfaces is always carried out prior to electropolishing or passivation to eliminate oxidise crusts that form on the surface during processes such as hot rolling, annealing, or welding. Pickling is done by immersion or by the application of a pickling gel. Normally the treatment is done by immersion in a chemical bath consisting of sulphuric acid (20-25%), hydrofloric acid (2.4%) and phosphoric acid (1-4%). Panels are again thoroughly rinsed with cold water under pressure. Electropolishing Electro-chemical polishing (DIN8590) creates a homogeneously polished surface by combining electrolyte solutions of phosphoric acid (30-50%) and sulphuric acid (30-50%) with electricity. The panel forms the anode of an electrolytic cell, while the cathode is usually formed by a plate in the stainless steel AISI 304. The principle is to remove material by selectively dissolving the surfaces to be treated in an electrolytic bath, under the action of the appropriate electrical current: a direct current at a voltage of 50-15V with a density usually between 0.2 and 0.5 A/sq cm. Benefits of electropolishing - reduction of surface roughness - elimination of burrs from processing - increase of the resistance to corrosion - enhancement of dirt repelling properties and aid to cleaning

| Material |

|

|

| Bearing bar specifications (mm) | 20 X 3 to 100 X 10; 25 X 5 X 3, 32 X 5 X 3, 38 X 5 X 3, 40 X 5 X 3, 50 X 5 X 3, 50 X 7 X 4, 55 X 7 X 4, 60 X 7 X 4, 65 X 7 X 4, 70 X 7 X 4, 75 X 7 X 4mm, or customerized |

|

| Bearing bar pitch (center to center) | 12.5, 15, 25, 30, 30.16, 32.5, 34, 40, 41.25, 45, 50, 60, 60.32, 80, 100 mm etc, or customerized | |

| Cross bar pitch (center to center) | 38, 50, 76, 100, 101.6mm etc, or customerized | |

| Surface Treatment | Nature, hot DIP galvanizing, paint spraying or following customer requirements | |

| Features | Anti-rust, durable, strong, safe, easy installation | |

| Packing | Wrapped with film and straps, wooden pallet packing | |

| Meeting steel grating standards | A) China: YB/T4001.1-2007 B) USA: ANSI/NAAMM(MBG531-88) C) UK: BS4592-1987 |

company introduction:

Anping Yuan special Co., Ltd. is located in the famous "screen of the township" Anping County, my company is a professional engaged in steel grid plate, grille plate, step plate, groove cover plate production and sales of large enterprises.

My company's main products are galvanized steel plate, splicing steel case board, platform, steel plate, pressure lock steel grid board, light steel case board, dense steel case board, I steel case board, heavy steel case board, tooth shape steel plate, flat steel plate, stainless steel plate, stainless steel grille plate, grate plate condole top, special grille plate, guardrail grille plate, Marine grille plate, glass fiber reinforced plastic grille plate, stainless steel trench cover board, ditch cover plate, perforated strainer, stair step plate, tree ladder pedals, stainless steel step plate, non-slip step, steel grille plate, mesh plate, etc.

Products are widely used in petroleum, chemical, port, electric power, transportation, paper, steel, food, municipal, real estate, manufacturing and other fields.

Our company has advanced management idea, scientific and systematic management method, flexible management mechanism, continuous technical innovation, adhere to the "quality first, customer first" service idea, our company sincerely welcome new customers to visit the factory.

Our service tenet: high quality products, low price, first-class service.

Yuante metal lets you: save money, save trouble, more worry.

Anping County yuan special wire mesh manufacturing Co., Ltd. is located in the country named "The hometown of Chinese wire mesh" and "Chinese wire mesh industry base" in Anping County, Hebei Province.

I plant adhere to technological innovation, scientific management, integrity management, pay attention to the introduction of advanced production technology and equipment, the implementation of standardized production, the adoption of ISO9000 international quality management system, from raw material procurement, production management, product testing and other key links strictly check, to ensure the quality of products, won the trust of customers.

Construction of wind-proof and dustproof walls

![]()

![]()

![]()

![]()

Q: Why to choose us? Any advantages?

A: The answer is Yes.

1) The most preferential price:Our offer will be reasonable, our price will be cheaper in the

same quality.

2) Customize: We can make the product as your request, specification,size and quality can meet

your request.

3) Mix order: We accept mix order, different specification and small quantity order.

4) Quality assurance:We have professional quality testing team.They will test the products before shipment.

5) After-sales service:Any question is welcome.

Q: Can I order one piece for sample to test the quality?

A: Yes, We recommend to check the sample before order.

Q: May I have your catalogue and price list for trial order in MOQ quantity?

A: All our products were shown on alibaba, please have a detailed looking and choose the interested products in our site.

Q: If I want cheaper quality, can you produce?

A: Yes, just send us your quality details, such as the material, what cheaper parts instead, etc, we will do that as your request and calculate the price.

Q: If I order big quantity, what's the good price?

A: Please send the details enquiry to us, such as the products specification,quantity and other requirements. We will make the most competitive quotation to you as soon as possible.