-

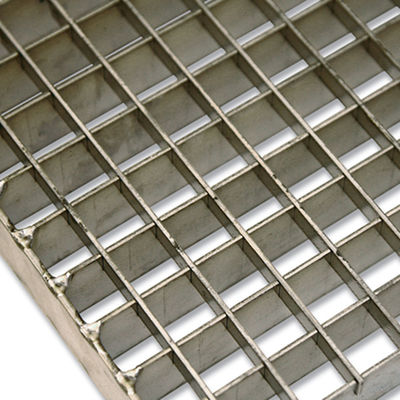

Industrial Steel Grating

-

Serrated Steel Grating

-

Heavy Duty Steel Grating

-

Grating Trench Cover

-

Anti Slip Grating

-

Steel Stair Treads Grating

-

Fiberglass Grating Panels

-

Stainless Steel Grating

-

Aluminum Bar Grating

-

Metal Fence Clips

-

Expanded Metal Sheet

-

Perforated Metal Plate

-

Welded Mesh Fence

-

Chain Link Fence

-

Gabion Wire Mesh

-

Stainless Steel Mesh

-

Metal Filter

-

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories.

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories. -

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient.

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient. -

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

Metal Materials Construction Structer Serrated Hot Dip Galvanized Grating Trench Cover Flat Bar 13mm Thickness

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Line | Bar Grating | Construction Type | Standard-Duty Welded |

|---|---|---|---|

| Bearing Bar Shape | Rectangular Bar | Series Type & Name | ZT-100 (19-W-4) |

| Product Spacing | 50x100 | Primary Material | Middle Carbon Steel |

| Bearing Bar Size & Shape | 32mm Height 5mm Thick Rectangular Bar | Bearing Bar Height | 32mm |

| Bearing Bar Thickness | 5mm | Bearing Bar Spacing | 30mm On Center To Center |

| Product Surface | Smooth | Cross Bar Spacing | 100mm On Center |

| Sizes (Width X Length) | 36" X 240" (Cut Sizes Available) | ||

| Highlight | Hot Dip Galvanized Grating Trench Cover,13mm Thickness Grating Trench Cover,galvanized metal grating trench cover |

||

Serrated Hot DIP Galvanized Flat Bar Multi-Size Steel Grating Trench Cover Grating 13mm Thickness Serrated Walkway Safet

Zhuote Metal Grating is manufactured from a swaging process that involves pre-punched load-bearing bars being swaged together with square crossroads. Various load-bearing bar depths and thicknesses are available through the aluminium range and this material is best suited in corrosive applications such as near the ocean or in water treatment plants.

All Zhuote Grating/Flooring products are designed and manufactured to comply with the requirements of National. Slip-resistant top surfaces such as serrated edge flat bar or quartz grit are available across the range and allow for slip resistance ratings of P4 and beyond. Surface treatments available in Anodized for aluminium.

Zhuote grating profiles cover an expansive range that covers requirements of the coal and iron ore industries, wine and beverage manufacturing, plant access walkways and heel-safe pedestrian access walkways to the current standards.

Standard profiles are available ex-stock in standard panel sizes however, we are able to manufacture and fabricate a range of profiles in China to suit your needs.

If you have a requirement outside of standard profile, contact our team today to discuss what we can offer you.

![]()

Reference:

![]()

| Parameters | Data |

| Bear Bar Type | Flat Bar, I-Bar, Serrated Bar, etc.. |

| Bearing Bar Size | 20x5mm, 25x3mm, 35x5mm, 40x5mm, 50x5mm, 60x5mm, etc.. |

| Bearing Bar Spacing | 20mm, 25mm, 30mm, 33mm, 40mm, 43mm or multiplier. |

| Cross Bar Type | Twisted Steel Rod, Flat Bar |

| Cross Bar Size | 3mm, 4mm, 5mm ,6mm or thicker |

| Cross Bar Spacing | 50mm or 100mm |

| Bearing Bar Length | Customerized from 1000mm to 6000mm or more |

| Cross Bar Length | Under 1200mm |

| Material Grade | Mild Steel(Q235B), Stainless Steel 304 or 316, etc. |

| Treatment Available | Hot dipped Galvanized, Anodized, Polished and Powder Coated |

Details

![]()

![]()

Products Pictures

![]()

![]()

![]()

Steel grid surface treatment:

Hot dip galvanized, cold galvanized, paint, dip anti-rust oil, do not deal with (general stainless steel do not deal with).

Method of making steel lattice plate:

Pressed-welded steel grid is made up of load flat steel and horizontal bar arranged in warp and weft at a certain distance. It is welded into the original plate by hydraulic resistance welding automation equipment of 200 tons, and processed into the product required by customers through cutting, opening, edge packing and other procedures.

Load flat steel spacing:

The center distance between two adjacent flat steel receiving loads is usually 30MM and 40MM.

Cross bar spacing:

The center spacing of two adjacent cross bars is usually 50MM, 100, two kinds, can be produced according to customer requirements.

Superiority:

Material saving:

The most economical way of material under the same load condition, correspondingly, can reduce the material of supporting structure.

Reduce investment:

Save material, save labor, save time limit, avoid cleaning and maintenance.

Construction is simple:

In the pre-installed support with bolts clamped or welded fixed, one person can complete.

![]()