-

Industrial Steel Grating

-

Serrated Steel Grating

-

Heavy Duty Steel Grating

-

Grating Trench Cover

-

Anti Slip Grating

-

Steel Stair Treads Grating

-

Fiberglass Grating Panels

-

Stainless Steel Grating

-

Aluminum Bar Grating

-

Metal Fence Clips

-

Expanded Metal Sheet

-

Perforated Metal Plate

-

Welded Mesh Fence

-

Chain Link Fence

-

Gabion Wire Mesh

-

Stainless Steel Mesh

-

Metal Filter

-

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories.

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories. -

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient.

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient. -

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

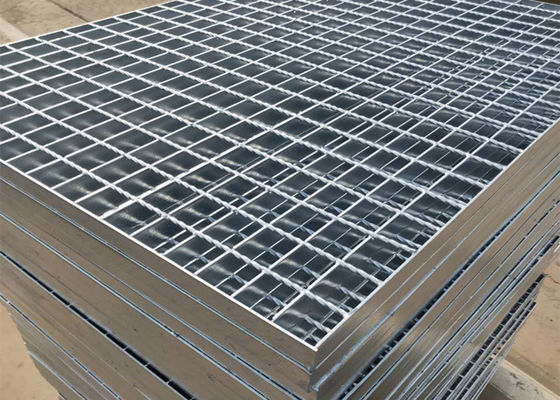

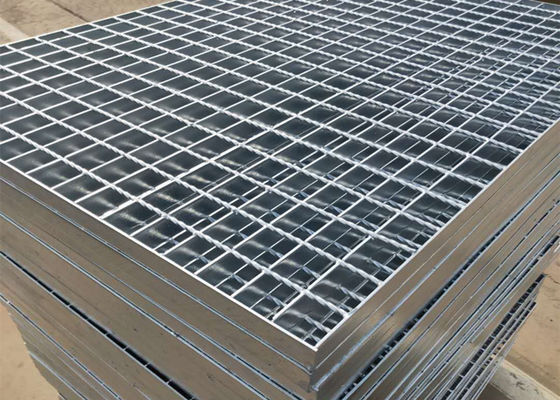

Platform Metal Hot Dip Steel Galvanised Grating Bridge Using 10mm Thickness

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Steel | Surface Treatment | Hot Dipped Galvanized,painted,untreated |

|---|---|---|---|

| Application | Trench Drains | Product Name | Heavy Duty Steel Grating Serrated Flat Bar Trench Drain Cover Prices |

| Color | Customized | Standard | ISO9001 |

| Length | 50mm-3000mm | Cross Bar Pitch | 50mm 100mm |

| Thickness | 3-10mm | ||

| Highlight | steel galvanised grating 10mm thickness,hot dip galvanised steel bridge grating,bridge steel galvanised grating |

||

Platform Gratings Metal Grating Hot Dip Galvanized Steel Grating

Desprictions:

Platform steel grid plate is also called platform steel grid plate, platform grid plate, is made of flat steel in accordance with a certain distance and cross bar arrangement, and welded into a kind of steel products with square grid in the middle,

Mainly used to do drain cover plate, steel structure platform plate, steel ladder step plate, etc.The bar is generally made of twisted square steel.

![]()

| Common Specification of Steel Grating | |

| Material | Low carbon, Q195, Q235 |

| Bearing bar type | Flat bar ,serrated bar ,I bar,etc |

| Bearing bar size (loading bar size) | 15,20,25,30,33,38,40,50,60,80 mm,etc |

| Cross bar pitch | 24 to 200 mm |

| Grating standard | YB/T4001.1-2007, ANSI/NAAMM(MBG531-88), BS4592-1987, AS1657-1985 |

| Feature |

Fine appearance,anti-corrosive,simple installation,lightweight, high load,anti-skid,prevent dirt deposition,ventilation,anti-explosion |

| Application | Floor walkway,industrial platform ,stair tread,metal ceiling |

| Product capacity | 5 days for 200 ton |

| Package | Pallets in containers packed by steel strap and worthy sea shipping or according to the customers' requirements |

1, by the flat steel width 65mm - 200mm thick 5mm - 20mm spot welding formation of hot dip galvanized steel grid plate for the heavy duty hot dip galvanized steel grid plate.

2, flat steel spacing 40mm) flat steel spacing 40mm hot dip galvanized steel grating plate for economic, lightweight varieties.

In the context of small span, it is an ideal choice.

3, (flat steel spacing 60mm) flat steel spacing 60mm bar for 50mm hot dip galvanized steel grid plate is suitable for mining and mining to solve the problem of mineral splashing on the surface of the plate, often designated for mining processing plants

4, (flat steel spacing 30mm) flat steel spacing 30mm hot dip galvanized steel grid for the industrial field widely used varieties.

In the series of commonly used hot dip galvanized steel grates, it has a strong resistance to surface impact

![]()

Feature:

1. Save material: the most material-saving way to bear the same load condition, accordingly, the material of supporting structure can be reduced.

2. Reduce investment: save material, save labor, save construction time, free of cleaning and maintenance. Easy construction: fixed by bolt clamp or welding on the pre-installed support, one person can finish.

3. Save time: No need to re-process the product on site, very fast installation.

4. Durable: Hot-dip galvanized anti-corrosion treatment before delivery, strong impact and heavy pressure resistance.

About Us:

Our expertise

In addition to our core manufacturing competencies, at our hearts, we are tool and die makers.

We have developed tooling, made parts and devised production solutions for a variety of industries.

This service is still offered to our customers today. Partner with us for your metal project or production tooling needs – We will treat them with the same care and devotion that you do.

Our facilities are backed up by modern CNC Toolroom equipment, which ensures production with precision.