-

Industrial Steel Grating

-

Serrated Steel Grating

-

Heavy Duty Steel Grating

-

Grating Trench Cover

-

Anti Slip Grating

-

Steel Stair Treads Grating

-

Fiberglass Grating Panels

-

Stainless Steel Grating

-

Aluminum Bar Grating

-

Metal Fence Clips

-

Expanded Metal Sheet

-

Perforated Metal Plate

-

Welded Mesh Fence

-

Chain Link Fence

-

Gabion Wire Mesh

-

Stainless Steel Mesh

-

Metal Filter

-

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories.

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories. -

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient.

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient. -

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

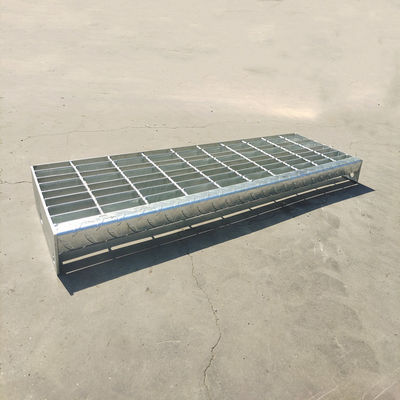

Hot Dip Galvanized Steel Ladder Treads Gratings Metal Step Stair Tread

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Steel, Q235, Low Carbon Steel | Type | Stairs, Plain Bar Grating, Serrated Bar Grating, I Bar Grating |

|---|---|---|---|

| Application | Floor, Shipbuilding, Walkway, Industrial Constructions, Power Plants | Size | Customized |

| Usage | Outdoor, Indoor, Shopping Mall/apartment/airports/office/commercial Building | Packing | Pallet, Wooden Box +iron Pallet, Pvc Films, Pallets In Containers Or As Per Request |

| Highlight | customized steel ladder treads gratings,galvanized metal step stair tread |

||

Hot dip Galvanized Steel ladder treads gratings, metal step Stair tread

Stair Treads/Stair Tread:

Stair tread is available in grating, plate, perforated plate and expanded metal. It's installed in the road or flooring, where the chances of skidding are there. This stair tread is available with or without angle frame. It easily retrofitted over existing grating or unsafe diamond checker plate assemblies. Meantime stair tread can be welded directly to current treads or stringers or can be bolted in place.Holes can be provided pre drilled for easy installation or can be drilled and countersunk in the field, without harming the surface. Therefore grating stair treads are ideal in wet and oily situations such as oil rigs, food processing plants and marine applications.

Stair tread creates a permanently slip resistant surface that is resistant to elements such as grease, dust and oil. When retrofitting over concrete steps, non-slip stair treads is routinely mounted into masonry anchors. Stair treads have become an integral safety component for extreme wear longevity and continual safety.They are available in thicknesses of 1/8″ up to 1/2″ and standard depths of 8″ – 12″. It's important that the correct grating load bar size and grating type is used based on the required stair tread span and loading. The table below is a basic guide used to establish the correct grating type required.

| Product Name | Stair Tread |

| Grating Style |

1. Flat Bar 2.Serrated Bar 3.I Flat Bar 4.I Serrated Bar |

| Bearing Bar Size |

25*3mm,25*4mm,25*5mm,30*3mm,30*5mm,32*3mm,32*5mm, 40*3mm,75*5mm,100*10mm |

| Bearing Bar Pitch |

Custom:15-90mm Routine Use:25mm,30mm,35mm,40mm |

| Twisted Cross Bar Pitch | 50,100mm or according to your requirements |

| Surface Process of Gratings |

1.Hot-dipped Galvanizing 2.Untreated 3.Painting |

| Grating Standard |

1.China:YB/T4001.1-2007 2.USA:ANSI/NAAMM(MBG531-88) 3.UK:BS4592-1987 4.Australia:AS1657-1985 |

| Steel Grade Standards |

1.China GB 700-88 2.USA:ASTM A36/A36M-96 3.UK:BS4360:1990 4.Australia:AS3679 |

| HDG Standard |

1.China:GB/T13912-2002 2.USA:ASTM A123/A123M-97a 3.UK:BS729 4.Australia:AS1650 |

| Steel Grade Standards |

1.China GB 700-88 2.USA:ASTM A36/A36M-96 3.UK:BS4360:1990 4.Australia:AS3679 |

| HDG Standard |

1.China:GB/T13912-2002 2.USA:ASTM A123/A123M-97a 3.UK:BS729 4.Australia:AS1650 |

Stair Tread Types:

1. Expanded metal stair tread

2. Grating stair tread

3. Perforated stair tread

4. Welded steel stair tread

Finished:

Self colour

Painted

Hot dipped galvanized

Advantages:

1. Stair treads provide a durable walking surface but features benefits like grating which allow for drainage and air flow. It ensure slip resistance for many years to come.

2. Stair treads have a protective finish such as paint or galvanizing. Without this surface treatment, stair treads can rust easily if exposed to moisture. Therefore it should be primed, painted or hot dipped galvanized to prevent corrosion. Hot dipped galvanizing is the preferred method for corrosion resistance.

3. Non-slip galvanized stair treads are formed to job specifications. Treads can be formed into a channel to completely cover an existing slippery stair.

4. Stair treads are easily retrofitted over existing concrete, grating or unsafe diamond checker plate assemblies. It can be welded directly onto current treads or can be bolted in place.

Applications:

Stair tread bar grating is a great choice for many industrial flooring applications. Smooth or serrated surfaces are available depending on your project needs for stair tread bar grating. Some common applications include:

Flooring

Walkway

Catwalk

Drain

Deck

Architectural

Steel Stair Treads Grating picture:

![]()

![]()

![]()

1. Quick response

We will reply our customer's inquiry ASAP within 24 hours.

2. Sample

Free sample is available if our customer are willing to undertake the courier fee. The courier fee can be deducted from the sebsequent order.

3. Layout drawing or shop drawing

We can provide the layout drawing or shop drawings for our customers' project solution.

4. Inspection

Our factory supports all our customers or nominated third party to our factory for inspection.

In addition, we can provide the instant photos during the production.

5. Strong package

We will do our best to offer strong package to keep the goods safe and sound when our customer receive them.

6. Timely delivery

Our strong supply capacity can help us to deliver the goods in time.

7. After-sale service

We will track the goods' use condition. Not only providing the tech support, but the solution of goods' quality.