-

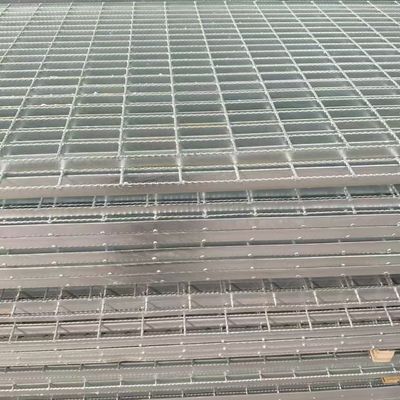

Industrial Steel Grating

-

Serrated Steel Grating

-

Heavy Duty Steel Grating

-

Grating Trench Cover

-

Anti Slip Grating

-

Steel Stair Treads Grating

-

Fiberglass Grating Panels

-

Stainless Steel Grating

-

Aluminum Bar Grating

-

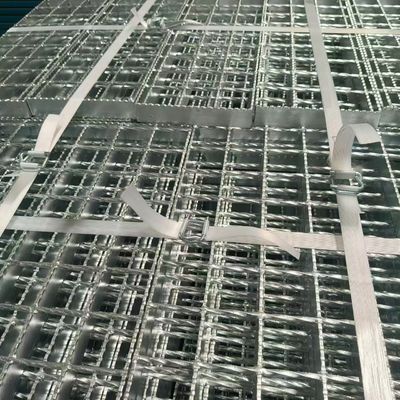

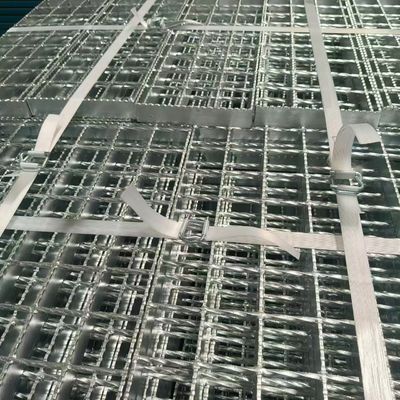

Metal Fence Clips

-

Expanded Metal Sheet

-

Perforated Metal Plate

-

Welded Mesh Fence

-

Chain Link Fence

-

Gabion Wire Mesh

-

Stainless Steel Mesh

-

Metal Filter

-

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories.

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories. -

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient.

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient. -

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

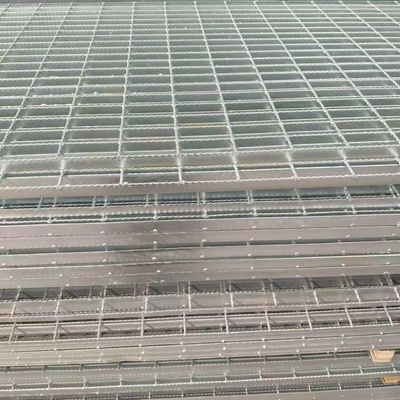

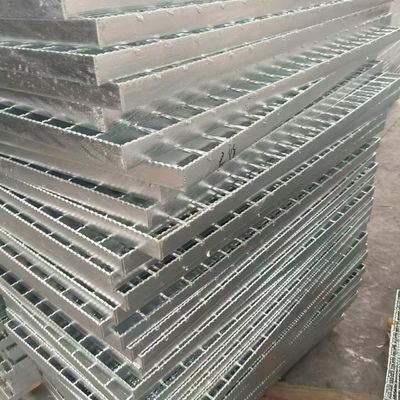

Steel Grating with Steel Frame, 40x4mm Bars Oil & Chemical Resistant Platform Flooring

| Place of Origin | Anping China |

|---|---|

| Brand Name | TT |

| Certification | ISO9001:2015 |

| Model Number | TT-2 |

| Minimum Order Quantity | 50m2 |

| Price | Negotiable |

| Packaging Details | Packing Suitable For Export,Also Depend On Customar Decide |

| Delivery Time | 3-5Days,Also Depend On the Quantity |

| Payment Terms | L/C, T/T |

| Supply Ability | 500M2 Per Day |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Heavy Duty Steel Grating, 3mm Thick Anti-Slip Anti-slip Fire | Production Method | The Pressure Welded Steel Grid Plate Is Made Of Load Flat Steel And Cross Bar Arranged According To Certain Spacing Longitude And Latitude, Using 200 Tons Of Hydraulic Resistance Welding Automatic Equipment To Weld Into The Original Plate, Through Cutting, |

|---|---|---|---|

| Application | Industrial | Bearing Bar Type | Serrated |

| Product Material Diversity | Raw Materials Of Steel Grid Plate Are: Flat Steel, Twist Steel, Pattern Plate. | Bar Spacing | The Center Spacing Of Two Adjacent Bars Is Usually 50MM And 100MM. |

| Size | Width Is Common 100mm, 150mm, 200mm, 250mm, 300mm, Etc. The Length Is Made According To Customer Requirements, And The General Length Is Between 1 Meter And 6 Meters. | Load Bearing Capacity | Heavy Duty |

| Highlight | Steel grating oil resistant flooring,Industrial steel grating with frame,Chemical resistant steel platform grating |

||

properties of products

Steel grid has a variety of excellent properties, including strong load-bearing capacity, good anti-slip, ventilation, heat dissipation, corrosion resistance and explosion proof. These characteristics make it widely used in many fields, such as stairs, platforms, stairs, Bridges and other structures in construction engineering, as well as in the fields of transportation, industrial manufacturing and municipal facilities.![]()

![]()

Technical Parameters

| Transport Package | Packaged By Steel Belt With Pallet |

| Size | As Per Drawing,commoned 32*5 |

| Features | Anti-slip, Drainage, Ventilation |

| Thickness | 2mm-5mm,5mm |

| Bearing Bar Pitch | 30mm, 40mm, 50mm, Etc |

| Load Bearing Capacity | Heavy Duty |

| OEM | Available |

| Grating Standard | YB/T4001-2007 |

Product material diversity

Raw materials of steel grid plate are: flat steel, twist steel, pattern plate.

The steel grid plate is an open steel member which is composed of bearing flat steel and cross bar according to certain spacing and fixed by welding or pressure lock. The transverse bar is generally made of twisted square steel, round steel or flat steel, and the material is divided into carbon steel and stainless steel.

Production method of steel grid plate:

The pressure welded steel grid plate is made of load flat steel and cross bar arranged according to certain spacing longitude and latitude, using 200 tons of hydraulic resistance welding automatic equipment to weld into the original plate, through cutting, opening, packaging and other processes.

Load flat steel spacing: the center distance between two adjacent load flat steel, commonly used 30MM, 40MM two.

Bar spacing: The center spacing of two adjacent bars is usually 50MM and 100MM.