All Products

-

Industrial Steel Grating

-

Serrated Steel Grating

-

Heavy Duty Steel Grating

-

Grating Trench Cover

-

Anti Slip Grating

-

Steel Stair Treads Grating

-

Fiberglass Grating Panels

-

Stainless Steel Grating

-

Aluminum Bar Grating

-

Metal Fence Clips

-

Expanded Metal Sheet

-

Perforated Metal Plate

-

Welded Mesh Fence

-

Chain Link Fence

-

Gabion Wire Mesh

-

Stainless Steel Mesh

-

Metal Filter

-

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories.

Andy SimpsonI'm a long-term partner of this factory. I've been on a field trip.The factory is strong and the grating quality is very good. I cooperated with this grating supplier in 2017.What surprised me was that this factory was very strong,and it was also one of the top local grating factories. -

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient.

David ZhangMy client told me that it was very smooth.The delivery speed is also very fast,I will receive the goods on the 7th day of the order.And the goods is inexpensive and convenient. -

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

Ajay ParateI have placed an oeder at this factory about FRP grating.The service is good and the grating is perfact.I'll come again.

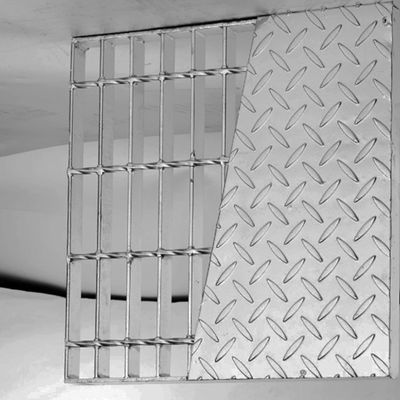

Galvanized 4mm Compound Steel Grating With Checker Plate

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Product Name | Compound Steel Grating | Raw Material | Q235 |

|---|---|---|---|

| Specification | G255/30/100 | Checker Plate Thickness | 3mm/4mm/5mm |

| Product Date | 5-8day | Payment Term | TT/LC |

| Highlight | 4mm Compound Steel Grating,4mm Metal Bar Grating,Compound Steel Grating Floor Drain |

||

Product Description

Galvanized 4mm Compound Steel Grating With Checker Plate

Galvanized Compound Steel Bar Grating Floor Composite Metal Steel Grating With Checker Plate Grating

Compound Steel Grating

Composite steel grid grating is composed of steel grid grating with certain load-bearing capacity and checkered plates. This type of bar grating may deform during the hot-dipped zinc coating process, so heavy-type steel bars with large gauges are typically selected for composite steel grid gratings.

The checkered plates are normally available in thicknesses of 3mm, 4mm, 5mm, or 6mm. Due to thermal stress generated during hot-dip zinc processing, the composite lattice steel plate may experience warpage, particularly when using larger models of steel grid plates.

Applications

Compound steel grating is widely used in platforms, corridors, bridges, well covers, stairs, and fencing for petroleum, chemical, power plants, waste treatment plants, civil engineering projects, and environmental projects. Its robust design and spanning capabilities make it extremely strong and safe for supportive structures on deckings, mezzanine floors, and elevated walkways.

Galvanized Compound Steel Grating Specification

| No. | Item | Detailed Description |

|---|---|---|

| 1 | Bearing Bar | 25x3, 25x4, 25x4.5, 25x5, 30x3, 30x4, 30x4.5, 30x5, 32x5, 40x5, 50x5, 65x5, 75x6, 75x10---100x10mm etc; I bar: 25x5x3, 30x5x3, 32x5x3, 40x5x3 etc US standard: 1'' x3/16'', 1 1/4'' x3/16'', 1 1/2'' x3/16'', 1'' x1/4'', 1 1/4'' x1/4'', 1 1/2'' x1/4'', 1'' x1/8'', 1 1/4'' x1/8'', 1 1/2'' x1/8'' etc |

| 2 | Bearing Bar Pitch | 12.5, 15, 20, 25, 30, 30.16, 30.3, 32.5, 34.3, 35, 38.1, 40, 41.25, 60, 80mm etc US standard: 19-w-4, 15-w-4, 11-w-4, 19-w-2, 15-w-2 etc |

| 3 | Twisted Cross Bar Pitch | 38.1, 40 50, 60, 76, 80, 100, 101.6, 120mm, 2'' & 4'' etc |

| 4 | Steel Grade | ASTM A36, A1011, A569, Q235, S235JR, S275JR, SS304, Mild steel & Low carbon steel, etc |

| 5 | Surface Treatment | Black, self color, hot dip galvanized, painted, spray coating |

| 6 | Grating Style | Plain / Smooth, Serrated /teeth, I bar, serrated I bar |

| 7 | Grating Standard | China: YB/T 4001.1-2007, USA: ANSI/NAAMM(MBG531-88), UK: BS4592-1987, Australia: AS1657-1985, Japan: JIS |

Galvanized Compound Steel Grating FAQ

Q: Are you a trading company or a manufacturer?

A: We are a manufacturer.

Q: How is your product quality guaranteed?

A: Our factory is ISO9001:2015 certified. All the products are 100% tested and inspected before delivery.

Q: How does your factory handle an order?

A: After receiving an order, we will discuss all details with customers and issue a PI for final confirmation. Customers will be requested to do 30% deposit before mass production starts. When production is finished, our QC will do final testing and forward inspection pictures and reports to customers. Customers will arrange balance payment before we inform their forwarder to pick up the goods.

Q: What's the lead time?

A: It varies according to different models and designs, but normally 3-4 weeks.

Q: Do you accept OEM or ODM?

A: Yes, we have professional R&D staff to process your drawings and requirements.

Q: How can I get a free sample?

A: We charge for sample making costs, but if customers place a bulk order after sample approval, the sample costs will be refunded.

Q: What is your payment term?

A: T/T and Paypal are both acceptable. 30% deposit, 70% balance payment before shipment.

Recommended Products